Element 10: Fire

10.1 Fire principles

10.2 Preventing fire and fire spread

> eliminate/reduce quantities of flammable and combustible materials used or stored

> control ignition sources, including suitable electrical equipment in flammable atmospheres

> use good systems of work

> good housekeeping

10.3 Fire alarms and fire-fighting

10.4 Fire evacuation

10.1 Fire principles

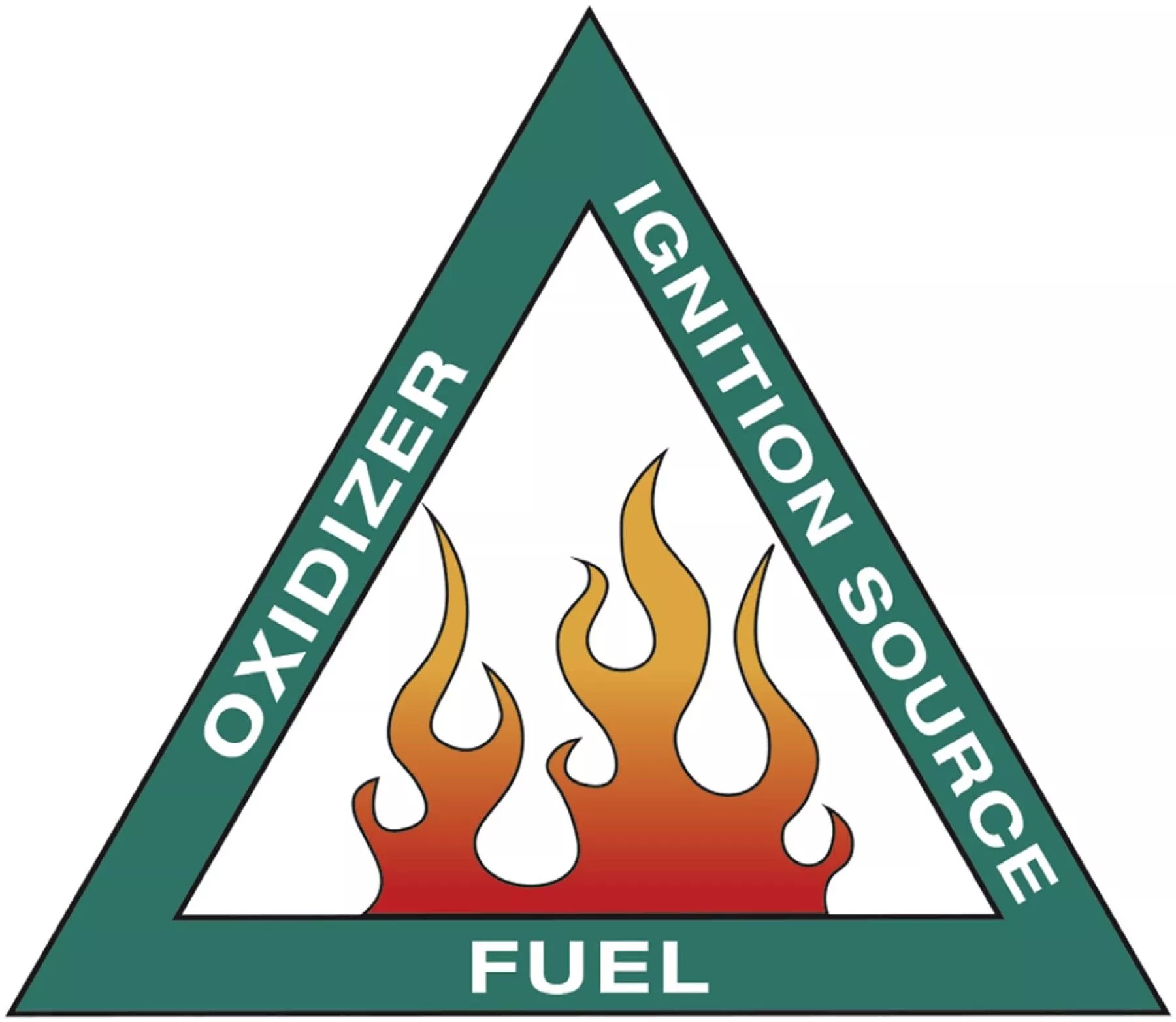

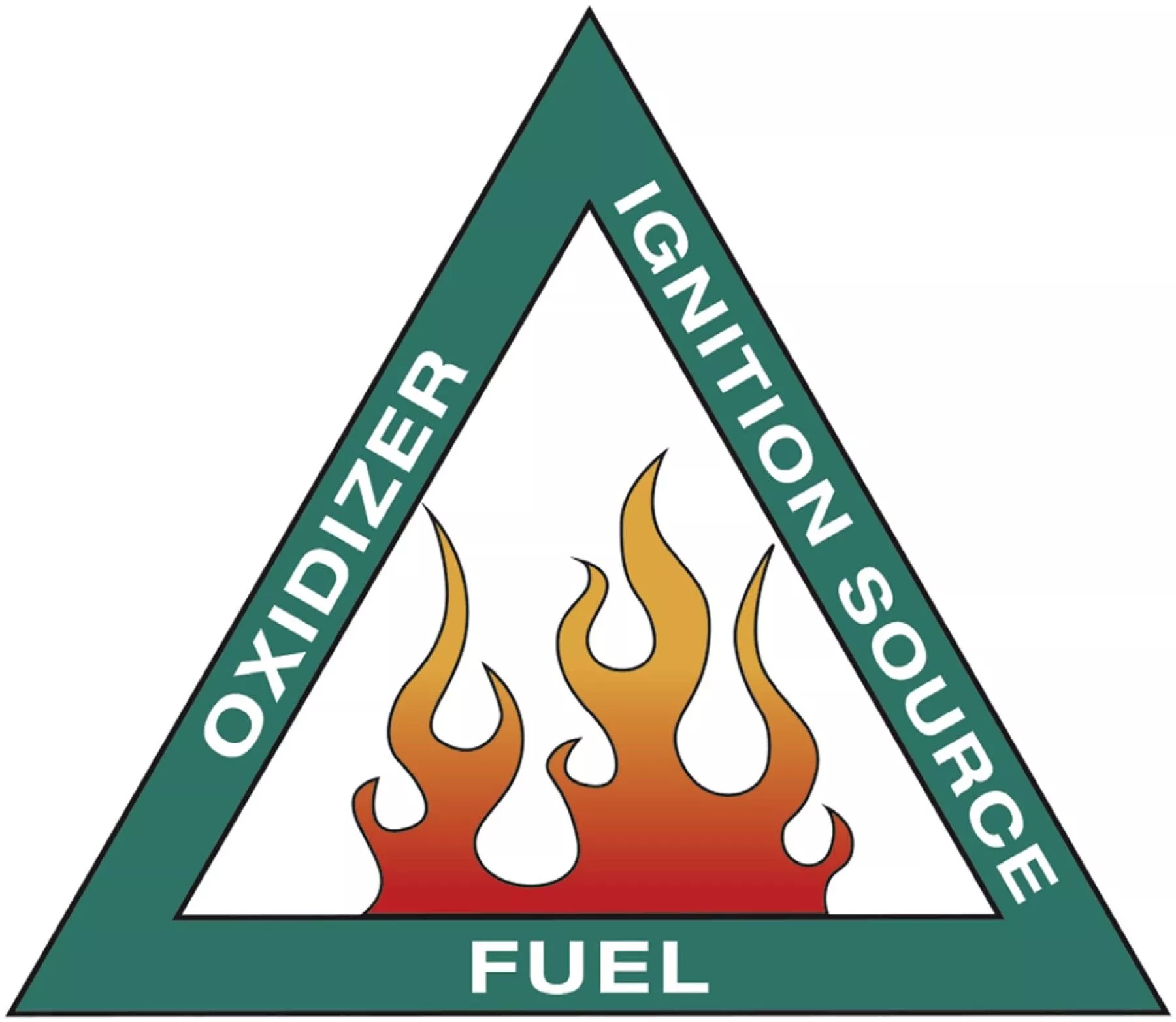

The fire triangle: sources of ignition; fuel and oxygen in a typical workplace; oxidising materials

The fire triangle

The “fire triangle” is a basic illustration of the three variables required for a fire to start and continue burning after it has begun.

All substances are capable of combustion if sufficient heat is applied to cause the molecules to decompose and emit vapour.

As the vapour or gas is produced, it is that which ignites, resulting in the release of further heat and the propagation of further reactions – the fire process has commenced.

As the material involved in the combustion or fire decomposes, the remaining material has less ability to respond, leading the fire to eventually die down and extinguish.

The decomposition of the material in this manner is known as pyrolysis, and the smoke produced by a fire is composed of unburned pyrolysis byproducts.

Fire initiators

There must be sufficient heat from an initiator or ignition source for a fire to ignite. There are ignition sources in every business and home. Open flames, hot surfaces, electrical sparks (internal or external), electrically generated arcs, friction (machines), chemical reactions, and even the compression of gases may be sources of ignition.

From the statistics, it is feasible to determine the sources of ignition and the number of times these “initiators” have been deemed to have caused a fire:

➤ Smokers’ materials

➤ Cigarette lighters

➤ Matches

➤ Cooking appliances

➤ Space heating appliances

➤ Central and water heating devices

➤ Blowlamps, welding and cutting equipment

➤ Electrical distribution

➤ Other electrical appliances

➤ Candles

➤ Other/unspecified.

In addition to those sources identified above other common sources of heat in the workplace include:

➤ Electrostatic discharges

➤ Ovens, kilns, furnaces, incinerators or open hearths

➤ Boilers, internal combustion engines or oil burning equipment

➤ Lightning

Fuel sources

Everything will burn given sufficient heat and the appropriate conditions. Obviously, some things will burn more readily than others, such as wood shavings or dust burning more readily than a solid piece of wood. These fuel sources are often classified into three categories (although these are sometimes subdivided).

Solids

Wood, cardboard, paper, hardboard, soft furnishings such as carpets and drapes, plastics, foam rubber, and even metal are examples of carbonaceous materials.

While the structure of solids is based on firmly formed particles, materials such as metals (unless reactive, i.e. magnesium) are extremely difficult to combust and require the use of considerable heat sources.

Certain solids are extremely “reactive” and may be categorised as “flammable” solids in accordance with UN Transport standards; they will be readily identified by a label or sign.

Liquids

Due to their capacity to emit vapour, they are significantly more likely to contribute to a fire. Liquids such as gasoline, paraffin, white spirit, thinners, varnish, and paints pose a substantial danger. Chemicals such as twin pack adhesives, acetone, and toluene also emit vapours, and these liquids provide an even larger risk due to their low flashpoint.

Gases

Common flammable gases in the workplace include natural gas and liquefied petroleum gas (LPG). The most popular LPG kinds stored in pressurised cylinders are butane and propane (i.e., for cooking, heating, plumbers’ torches, etc.); also, dissolved acetylene and oxygen mixtures are used in welding operations. As with the flammable vapours emitted by flammable liquids, gases not only pose a considerable risk of fire but also of explosion.

Dusts

Several common and occupational elements can generate dust, including wood, coal, grain, sugar, synthetic organic compounds, and certain metals. If ignited, a cloud of flammable dust in the air can erupt dramatically.

Oxygen

Oxygen is the final element of the fire triangle to be explored. Oxygen is a component of the air we breathe (19.6 %) and is therefore available in all areas where people may survive.

As previously said, the oxygen supply can influence fire behaviour; therefore, understanding how the supply can be increased or decreased is essential when considering control elements. Ventilation and air handling systems, as well as oxygen cylinders (for medical use and hot work/cutting work), can increase the oxygen supply. Oxygen can also be released by chemical reactions, namely those involving ammonium nitrate (fertilisers), sodium chlorate (pesticides), hydrogen peroxide (water treatment, hair care), and chromate (variety of industrial processes). It should also be noted that oxidizers exhibit very exothermic reactions when they come into contact with other chemicals, especially flammable ones. Oxidizing agents can also boost the combustibility of chemicals that do not ordinarily burn easily in air, or they can reduce ignition temperatures to the point where materials burn more quickly and fiercely..

Classification of fire

The classification of fires according to their types. Five classes are outlined in BSEN 2. The classifications help identify not just the type of fire, but also the type of extinguishing media required to extinguish or control the fire.

Class A – fires involving solid materials, typically of an organic nature, such as wood, cardboard, paper, hardboard, and soft furnishings such as carpets and draperies, where combustion typically occurs with the creation of blazing embers.

Class B – fires involving flammable liquids, such as gasoline, paraffin, white spirit, thinners, varnish, and paints, or flammable solids, such as candles (wax) and fats.

Class C – fires involving gases like LPG (butane, propane) or natural gas.

Class D – fires involving metals such as sodium, lithium, manganese, and aluminium in swarf or powder form

Class F – fires involving cooking substances such as vegetable or animal oils and fats in cooking gadgets. These fires are very difficult to extinguish because they retain a substantial amount of heat, allowing the chemical reaction to resume.

Notably, there is no classification for electrical fires, as electricity does not involve any combustible materials that can be put out. Electrical circuits and appliances, cables, etc, can be extinguished either with a non-conductive extinguishing substance or by isolating the supply and extinguishing the real material (given its own “class”).

Principles of fire spread

After a fire has started and there is sufficient fuel and oxygen to maintain it, there are three recognised routes for it to spread within a structure: convection, conduction, and radiation. There are also the impacts of direct combustion and heat transport to consider.

Convection

Owing to its qualities, hot air rises; this is seen when smoke from a bonfire rises and disperses into the atmosphere or when a fire is lit in a grate and rises through the chimney. When combustible materials are subjected to extreme heat, they emit a flammable vapour that initiates the convection process. When heated, these vapours expand and become less dense than air. When they ascend, they leave a region of low pressure that is immediately replaced by cooler, unheated air. This fresh air is subsequently combined with the vapour and heated, contributing to the increase in temperature. It is a cyclical process that continues to assist the fire process. The most common source of fire spread within buildings and structures is convection. During a fire, hot gases and vapours (smoke and heated air) will rise to the highest accessible level through stairwells, lift shafts, and service risers. They then establish a layer at that height, which they use to spread out horizontally until they are discovered. When the temperature of the smoke and, subsequently, the hazardous gas/vapour layer rises, heat is reflected downwards and may burn nearby combustible things. Recent research also indicates that the unburned fuel (pyrolysis products that have not been burned) in the smoke can reignite when it reaches its spontaneous combustion point, resulting in a significant increase in temperature. This temperature increase has the potential to create a flashover or explosion if a fresh supply of oxygen is introduced (window glazing fails). Clearly, there is a significant difference between a fire that starts in a confined location, such as a structure, and one that starts in the open air, and this must be taken into account when designing buildings to prevent smoke and fire spread and allow people to escape safely.

Convection and the effects of smoke

Although it is essential to limit the spread of fire within a structure, it is also crucial to consider the rate of spread and the impact of the smoke produced by the fire as it burns. As a fire spreads, it will generate vast volumes of smoke, which will typically move ahead of it and rapidly fill a structure. This creates a poisonous and/or suffocating hazard for the building’s inhabitants. Smoke also lowers visibility and obscures escape routes; this, combined with people’s natural aversion to move through or into smoke, can cause or exacerbate panic, which leads to confusion and reduces the likelihood of safe escape.

Conduction

Conduction is the transfer of heat through a substance. The ability of conductors to carry heat varies greatly depending on the type of material; for example, metal is a significantly better conductor than brick. It should be emphasised that conduction can occur in solids, liquids, and gases; nevertheless, in the context of building fires, solids are the most common conductors.

A fire in one room can spread to adjacent rooms via heat conduction through the building’s structure (walls, ceilings, etc.), particularly through metal pipes or frames used in building construction. The heat can then ignite substances in direct contact with the surface or radiate away from it. This can boost the temperature of nearby materials to the point of spontaneous combustion, thereby spreading the fire. The relative conductivity of building materials is consequently a significant aspect of a structure’s or building’s fire resistance.

Radiation

Radiation is the transport of thermal energy in the form of electromagnetic waves that heat solids and liquids (but not gases) in its path. Paths of fire radiation require no interaction between bodies and flow independently of any object intervening in space. If electromagnetic radiation is not absorbed by fire-resistant materials, it can radiate through windows and cause fires to spread to many compartments/rooms. As with a heater or an open fire, fires can spread to combustible goods left to dry or from one structure to another when heat from a fire radiates through windows to an adjacent building, igniting combustible contents in the second building..

Direct burning

When combustible materials come into direct contact, there is a physical transfer of heat from the ignition source to the combustible material, resulting in the release of volatile substances that ignite and spread the fire. It is true that direct burning utilises one or more of the previously discussed methods of heat transfer; however, it is appropriate to mention this method because a significant proportion of fires are ignited in this manner, and when heated to an ignition temperature by coming into contact with a burning material, it causes fire to spread.

Causes of fire

Accidental fires

The term accidental fire refers to all fires other than those set intentionally or maliciously.

There is a vast variety of causes for workplace fires. They will, to some extent, represent the function of the workplace. In many organisations, a workplace may be a vehicle, such as in the case of a long-distance truck driver employed by a transportation company. It is also beneficial to investigate the causes of fires in vehicles.

Considering the available statistics, it is clear that the most prevalent causes of significant accidental fires in the workplace fall under the following categories:

➤ Electrical appliances and installations

➤ Cookers, associated cooking equipment and installations

➤ Naked lights and flames

➤ Heaters and heating systems

➤ Chemical and LPG (hazardous materials)

➤ Smokers and smokers’ materials

➤ Waste and waste management systems

➤ Other significant causes.

Arson

Arson can be defined as the deliberate or willful act of lighting fire to a structure or piece of property, whether it be an industrial facility, a residence, a vehicle, or any other similar object. In the United Kingdom, arson has become the leading cause of big fires.

At its worst, arson can result in loss of life and major financial ramifications, as is the case with any fire. But, continuous and pervasive minor arson attacks also generate a very negative (and aesthetically damaging) tone in disadvantaged places and communities. In some locations, arson now accounts for 70% of all fires, and in some inner-city neighbourhoods, an astounding 82%. Over the past decade, the number of arson fires attended by the fire service in the United Kingdom has more than doubled, and now exceeds 85,000 annually.

During the same time period, the rate of increase in the number of casualties caused directly by arson assaults has been comparable.

10.2 Preventing fire and fire spread

As demonstrated in the preceding section on arson prevention and control, the preventative techniques for decreasing the risk of fire and explosion in the workplace are applicable to the vast majority of industry sectors. The primary causes of fire typically vary only in minute specifics and frequently involve hazardous operations and sites, e.g. COMAH sites; otherwise, the reasons are consistent, especially when the “human component” is involved. Thus, this part will cover broad recommendations, with specific topics explored under each of the sections. By formalising and disseminating a written policy, a complete prevention approach should incorporate the overall preventative and protective measures for each element addressed. The policy document should address the following:

➤ A description of the specific policy being handled, such as hot works.

➤ A section describing organizationally who is responsible for what, e.g., who is responsible for securing a contractor to test electrical equipment, or the role of personnel in doing visual inspections.

➤ Detailed procedures for conducting risk assessments and implementing controls, such as determining the number of fire marshals needed and their training, are required.

➤ Details of any monitoring or measuring of performance, such as the signing off of a permit to work system, should also be included, as well as whether they were completed adequately and run efficiently.

➤ How the aspects of the individual policies will be reviewed and audited to determine their efficacy or wastefulness. For instance, gas heating equipment that is no longer in use may still be included on an inspection aide memoire, the policy appears to still cover gas equipment, and individuals continue to get training in the safe use of gas cylinders..

Electrical appliances and installations

Electrical fires are second only to arson as the leading cause and hazard of workplace fires. A variety of management steps are likely to be incorporated into the management system described above in order to limit the risks connected with electrical appliances and systems. Only procure electrical appliances and equipment from a reputable (preferably authorised) vendor. Prior to acquisition, a risk assessment should have been conducted to ensure the equipment is safe and suitable for its intended use.

Portable appliance testing (PAT)

The frequency of inspections and tests should be determined by the kind of use for portable electrical equipment. Preferably, electrically portable equipment should include labels indicating that it has been inspected and tested and is in satisfactory condition.

More regular testing is conducted on electrical equipment used in harsher settings, such as construction and hilly operations. Electrical installations, whether temporary or permanent, as well as electrical equipment and apparatus, should be protected by a variety of measures, such as residual current devices (RCDs) that protect humans from electrical shock, fuses, and miniature moulded circuit breakers (MCCBs) that protect electrical equipment from overheating and short circuits. Provisions should be made to ensure that all electrical work on installations and/or electrical equipment is performed solely by trained, qualified, and competent electricians who are conversant with the relevant systems. Electrical safety systems such as those described above will also assist in reducing the risk of fire caused by vermin-caused damage to installation cabling; however, these systems should be supported by active management to control vermin in order to avoid or minimise the risk of fire from these areas. The hazards associated with electrical equipment, any special design difficulties, restrictions, and signs and symptoms of deterioration or wear should be explained to all staff members who will be using electrical equipment. To aid in controlling electrical safety, documented systems to provide documentation of testing, inspection, etc., as well as a defect reporting system, should be considered.

Cookers, associated cooking equipment and installations

The use of electrical cookers and cooking equipment necessitates the consideration of management systems that address electrical safety-related issues. In addition to the management methods described above, a planned preventive maintenance (PPM) programme should include heat-controlling devices such as thermocouples, as it is unlikely that portable appliance testing can completely eliminate the risks posed by such equipment.

Gas cooking equipment and installations must be installed by a Council of Registered Gas Installers member (CORGI). Installing gas to appliances should involve either fixed piping or protected/armored flexible tubing. LPG petrol cylinders must be located outside of buildings and shielded from unwanted intervention in the case of temporary cooking supply and installations (e.g., during construction). As technology progresses, petrol systems and appliances should ideally fail to secure themselves in the event of an emergency, like as a fire. It is expected that gas supplies to appliances and installations will be linked to alarm/detection systems that, when activated, will automatically shut off the gas supply. Notably, gas supplies should not be able to be re-energized after an emergency in a manner that allows gas supplies to “free flow” in the presence of an ignition source to regulate the gas release. With modern systems, such as those found in hotels and restaurants with big kitchens, an extra safety measure, such as the deployment of fixed firefighting installations, can be implemented. They will be discussed in greater detail in subsequent chapters. As with electrical testing, all systems should be subject to routine inspection and maintenance by a certified engineer in accordance with the manufacturer’s or installer’s maintenance programme.

Naked lights and flames

The most effective method for reducing fire risks from this source is to prohibit the use of naked flames in the workplace. Replacement of hot work and flame-generating equipment, such as oxy-fuel equipment, must be viewed as the initial step in lowering the risks associated with this area. In terms of practical operations, the use of compression plumbers’ fittings as opposed to soldered connections is a good example of a situation in which this substitution eliminates the danger totally. When the use of naked flames cannot be avoided, formal operating procedures, safe work systems, additional levels of supervision, and suitable levels of formal monitoring on a regular basis may be used to limit the risk. The burning of trash in the workplace or on a building site should be avoided at all costs, both because of the inherent fire risk and to maintain compliance with the Environmental Protection Act, which mandates the management of air emissions. When purchasing high-heat-emitting lighting devices, such as halogen lights, a risk assessment should be conducted to determine their suitability. If such units are necessary, control mechanisms, such as restricting their use to regions devoid of combustible materials and flammable vapours, should be considered. Ensuring that higher-risk lighting undergoes planned preventative maintenance, specifically on their retaining hinges and brackets, will guarantee that the fixtures remain upright and away from surfaces that could catch fire.

Heaters and heating systems

The preceding paragraphs describe the risks connected with electrical and gas systems, which are also associated with the energy sources utilised by heaters and heating systems. Poor design, improper installation, and a lack of scheduled preventive maintenance are all causes of fire, as previously noted. Therefore, it is necessary to guarantee that systems are developed, installed, and subject to preventive maintenance as planned. Systems should be designed so that if a hot product can heat areas such as ducting, which runs through a building, the areas should be lined with fire/heat resistant materials to prevent them from coming into contact with combustible materials; therefore, hiring competent designers is a crucial risk management step. The installation of heaters and heating systems must be performed by qualified engineers adhering to the design requirements. It is also likely that these experts will be retained to perform the system’s scheduled preventative maintenance to ensure that it remains safe and functional. The maintenance schedule must take into account rotating or moving parts that must be greased to prevent them from drying out. It is likely that combustible materials will not come into contact with any component parts of a heating system if the system is designed correctly; however, due to the human factors involved, physical barriers, awareness training, and regular inspections will likely be required to ensure that combustible or flammable materials do not come into close proximity with the systems or impede air circulation by blocking ventilation grilles, etc.

Chemicals and LPG (hazardous materials)

The Control of Substances Hazardous to Health Rules apply to the vast majority of chemicals used in the workplace, which are categorised as CHIP substances (COSHH). Certain chemicals and liquefied petroleum gas (LPG) may also be subject to the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR), which mandates the appropriate management and control of risk. Regarding the management of chemicals and LPG, formal procedures must be developed, executed, and monitored for their usage, storage, transport, and disposal. Training in all relevant areas, including the handling of chemicals and LPG gas cylinders, is essential for ensuring the safety of everyone in the workplace and anybody else who may be affected.

In many instances, the safety principles pertaining to both chemicals and LPG are similar, therefore it is intended to treat these general safety principles for each hazardous material as a single entity, with specific differences underlined.

Substitution

If at all possible, the use, storage, etc. of combustible chemicals and substances and LPG should be avoided. The same holds true for liquids with a low flashpoint. Alternative chemicals, compounds, or liquids that are either non-combustible or have a higher flashpoint may serve as safer substitutes. Reactive chemicals whose qualities are non-flammable on their own, but may react violently or even explosively when combined, must also be examined in connection to their substitution with less reactive materials.

Storage

Where substitution is not possible, the provision of secure storage must be considered as a key factor in decreasing the fire and explosion hazards associated with the hazardous items. In an ideal situation, procedures should be established to store flammable liquids, gases, and chemicals apart from other processes and general storage facilities. This is most effectively attained through physical separation. Alternately, a physical barrier, such as a wall or partition, could be combined with a storage system or container. If the storage facility will be housed within a building and hazardous items will be handled in the area surrounding the facility, fire-resistant isolation from other portions of the building or workplace should be addressed.

The storage arrangements for combustible compounds and LPG will rely on the quantity and nature of the hazardous items, as well as the availability of storage facilities. External storage arrangements – for storing big quantities (50 litres or more), an exterior storage facility that includes the following considerations should ideally be provided:

➤ Storage and separation from other processes (flammable compounds must be stored separately from other hazardous substances and materials, such as oxidizers and LPG, etc.):

➤ By physical distance

➤ Fire wall

➤ Protection against unauthorized access, locking mechanisms, physical walls and fences

➤ Located in a well-ventilated region on impermeable ground

➤ Assess the impact of potential heat from a fire within or outside the boundary of the premises on the containers, as well as the impact of a fire within the storage facility on buildings, equipment, and people within and outside the facility.

➤ Positioned far from ignition sources (or where electrical supplies are intrinsically safe)

➤ Environmental protection arrangements:

➤ Bunded facility (110% of contents)

➤ Interceptors to capture potential release

Larger volumes (more than 300 kg) of LPG gas cylinders must be stored in a manner similar to that of flammable liquids. In addition to providing suitable levels of signs on site, it will be necessary to create and implement formal systems of work that:

➤ Keep trash and flammable materials well away from the cylinders, and keep nearby weeds and grass trimmed down (avoid using a chlorate-based weedkiller, as it can be a fire hazard in itself)

➤ Avoid electrical devices, automobiles, bonfires, and other ignite sources from coming close to the cylinders.

➤ Avoid smoke when replacing cylinders.

➤ Restrict non-installation or storage personnel, especially youngsters, from obtaining access to it (construction sites particularly)

➤ Keep vehicles far away from the structure (fire and impact hazard)

➤ Prevent piping from unintentional damage by ensuring correct routing and support. In the case of subterranean routing, schematic diagrams of the pipe paths are created to prevent anything from being placed in the ground that could damage the piping.

➤ Permit prompt reporting of any equipment failure or damage to the provider.

Internal storage – where flammable substances can be stored in specially designed separate buildings that are safe by location, the same control measures as those required for outdoor storage may be used, with the additional requirement that the building be constructed primarily of non-combustible materials and that the roof be made of lightweight materials. The roof would readily open to relieve the impacts of an explosion, thus providing explosion relief.

Ventilation of any building used to store flammable materials must also be considered; ventilation openings or bricks must be positioned at both high and low levels to facilitate air flow within the building/store. The apertures may not provide ventilation to adjoining structures or exterior locations that may contain ignite sources. The needed number of apertures (as a percentage of the total floor area) will vary depending on the substance housed, such as 1% flammable liquid and 2.5% flammable gases.

Depending on the procedures in which lesser quantities of combustible compounds and LPG are utilized, the storage options for these substances will vary. Any containers that will be used to store flammable liquids must be designed and constructed in accordance with the applicable standard. Also, containers must be of a performance-tested kind, with tight-fitting lids and spill-resistant tops to avoid leakage if they are knocked over. For these containers and their packing to be compliant with shipping regulations, there are specialized standards available. The containers’ material must be compatible with the liquid’s chemical and physical qualities to prevent any chemical or physical interactions that could lead to leaks. In addition, containers may require corrosion protection, such as painting, and plastic containers are frequently degraded by natural light, which can be mitigated by shading the container appropriately. LPG cylinders can also be degraded by corrosive atmospheres, especially in relation to certain chemical activities; consequently, their use and storage should match the conditions of the workplace and they should be stored outside. Consideration must be given to storage within the real workplace where the combustible material or LPG will be used. Ideally, plans for external storage should be made; if this is impractical, the following must be considered:

➤ Limit the amount of stored and utilized combustible materials and LPG to an absolute minimum.

➤ Storage measures should be provided for flammable liquids that are distinct from other substances, including LPG – up to 50 litres may be stored in a fire-resistant cabinet or container within the work area.

➤ Every storage should be equipped with security features that provide only authorized access.

➤ Spill protection must be supplied at the storage facility.

➤ Containers with flammable liquids should always be replaced in the storage after use, and lids should be provided to prevent vapour leakage and spillage.

➤ Storage of LPG (up to 300 kg) should ideally occur in the open air, but if kept in a workplace, adequate ventilation is required.

➤ For flammable liquids, proprietary safety containers (such as dash pots used in the printing industry) should be equipped with self-closing lids.

➤ There should be no dispensing or decanting of flammable substances within or near to a store. Provisions for ventilation and extraction systems should be made for such operations.

➤ The storage facility must be placed distant from sources of ignition.

➤ Signs indicating the flammable storage facility, including ‘no smoking’, shall be displayed.

➤ An inventory of the drugs should include, at a minimum, the substance’s name, type, and quantity.

➤ Plans for the proper storage and disposal of materials such as rags, cloths, etc. that may have been used to apply the liquids or mop up spills.

For instance, metal containers with tight-fitting, self-closing lids and daily/shift-ending removal.

Training –

As stated at the beginning of this section, training is essential for guaranteeing the successful management of a company’s fire safety, particularly in respect to combustible compounds and LPG. Each training program must include instruction on the proper handling, storage, and disposal of these hazardous substances. The following is an example of a program’s structure:

➤ The sorts of combustible materials in use, their qualities, and their dangers

➤ General guidelines for the safe handling of substances and plant operation

➤ Use of personal protective equipment and apparel

➤ Housekeeping arrangements

➤ Incident and defect reporting, including spills and minor leaks

➤ Detailed instructions on specific equipment, plant, and processes

➤ Procedures for emergency situations, such as raising the alert, using the proper firefighting equipment, deploying skills, etc.

Smokers and smokers’ materials

As in each of the preceding sections, the primary steps in the management of smokers and their discarded smoking materials consist of establishing a policy regarding the formalization of the standards, determining who is responsible for what, implementing practical preventive control measures, and training and educating all staff and those who may be affected.

Numerous organizations have excellent smoking policies based on the provision of designated smoking spaces and the prohibition of smoking anywhere else. Less effective are regulations based on a complete ban; however, this merely helps to drive smokers into out-of-the-way, quiet areas such as the plant room, storage areas, toilets, and emergency escape staircases with no disposal preparations, where a small fire has the potential to grow unnoticed. The provision of smokers’ booths strategically located away from combustible materials and any potentially flammable atmospheres, along with the provision of facilities to dispose of used smokers’ materials (ash trays, metal bins, etc.), provides practical solutions for the management of this risk; however, this cannot always be guaranteed in places of employment. As the ban on smoking in public areas takes effect, places of public entertainment and public assembly will undoubtedly benefit from being smoke-free zones; however, it is likely that facilities such as nursing homes will still require an effective management strategy to reduce the risk of fire from smoking materials. These agreements will presumably include:

➤ Establishing a monitoring system to ensure smoking is restricted to specific locations

➤ Supply of ashtrays or waste containers made of metal or glass

➤ Assuring, when ashtrays are emptied (before leaving the area at night, for instance), that all materials are extinguished before being placed in external bins that are separate from combustible debris.

➤ The upholstered furnishings in the smoking areas are fire resistant (chairs, curtains etc.). As part of an overall management strategy that includes welfare provisions for their employees, many successful organizations also encourage staff to quit smoking by providing advice, guidance, and support from both internal and external occupational health advisers and by running effective awareness campaigns.

Building construction and design – preventive and protective measures

The first step in guaranteeing appropriate levels of fire safety for the building and its occupants in the event of a fire is to design and maintain a “safe” building. Without a secure structure, management’s attempts to develop procedures that prevent fires and ensure emergency evacuation will have little or no effect.

The fundamental characteristics that provide the foundation for building and life safety in all structures are:

➤ Elements of structure

➤ Compartmentation

➤ internal linings.

Elements of structure

An element of structure is defined as a part of a structure that supports the structure, i.e. a load-bearing component, such as:

➤ Any part of a structural frame (beams and columns)

➤ Any load-bearing wall (other than part which is only self-load-bearing)

➤ A floor or any element that supports a floor.

A roof structure is not considered a structural element unless it supports another structural element or serves as a floor. The structural elements should continue to function during a fire. They must continue to support and maintain the fire protection for floors, escape routes, and access routes until all occupants have either escaped or been rescued. In order to accomplish this, load-bearing structural elements must have a demonstrated level of fire resistance. The degree of a building’s fire resistance is dependent on its use, size, and location.

Elements of structure are required to have specific fire resistance in order to:

➤ Reduce the risk to the residents, some of whom may not quickly escape the building.

➤ Minimize the potential threat to firefighters engaged in firefighting or rescue operations.

➤ Avoid excessive fire damage and building collapse.

➤ Avoid excessive heat transfer to other structures and buildings.

Junctions

In a construction that is intended to provide some fire resistance, it is vital that the junctions between the various structural parts do not create weak points in the fire protection. Therefore, it is essential that the joints between all structural elements that comprise a compartment prevent the passage of fire for at least as long as the duration of fire resistance of any of the parts it connects. In certain circumstances, such as the rooftops of terraced buildings and buildings that are adjacent, the compartment walls extend through the roofs and walls that comprise the compartment.

Compartmentation

Compartmentation refers to the division of a structure into compartments. Each compartment is divided by walls and/or floors, limiting the growth and spread of fires within buildings. Proper compartmentation lowers the damage produced by a fire’s heat and smoke, which has immediate and important implications for the business continuity and resilience of the building’s occupants. Compartmentation is also utilized to restrict the spread of fire between adjacent buildings. It is possible to partition a space horizontally inside a floor or vertically between floors. Compartmentation is also utilized to provide relatively secure spaces for persons escape a fire..

Materials of construction

Buildings frequently attain fire resistance due to the intrinsic properties of the building materials utilized. Architects and builders choose various materials for both aesthetic and functional purposes. These are some typical construction materials:

➤ Brick and concrete

➤ Steel

➤ Plasterboard

➤ Glass

➤ Steel sandwich panels.

Brick and concrete

When constructing with bricks or concrete blocks, suitable fire resistance is obtained by ensuring that the joints at the walls and ceilings are sound and by giving sufficient vertical stability through the placement of piers and/or corners. When mass concrete is utilized, it is reinforced with steel to provide the required strength.

Steel

Steel is utilized because it is lightweight, durable, and somewhat flexible. The primary disadvantage of employing steel for structural elements is that it has a low melting point and loses 60 percent of its strength at temperatures around 600oC.

The steel components of a building must be shielded from the heat of a fire in order to prevent the structure from collapsing prematurely, as building fires frequently reach temperatures of 1 000 degrees Celsius. Protection methods for structural steel include:

➤ Encasing in concrete

➤ Enclosing in dry lining material, e.g. plasterboard

➤ Coating with cement-based materials

➤ Coating with intumescent materials.

Plasterboard

Plasterboard’s fire resistance results from its composition of noncombustible substance, typically gypsum. A wall constructed from 12 mm thick plasterboard and properly sealed at the joints will provide 30 minutes of fire resistance. Plasterboard has minimal strength or load-bearing capacity, which is a drawback. Its durability is contingent upon the strength of its supporting structure (often wooden or metal studwork) and its resistance to mechanical harm.

Glass

The advancement of glass production technology has led to glazing with a variety of specialized applications, such as:

➤ In internal doors as vision panels

➤ As internal and external doors

➤ As partitions and compartment walls

➤ In roofs, floors and ceiling

➤ In escape and access corridors.

The structural integrity of glass elements is entirely dependent on the support systems, such as beading, seals, and fasteners. While evaluating the fire resistance of glass, it is essential to locate proof that it meets the required fire resistance. Fire-resistant glazing should be stamped permanently with at least the product name and manufacturer’s name. The mark must be completely legible and noticeable.

It should be noted that there are numerous proprietary types of fire-resistant glass, many of which have names that seem similar.

The main glass types are as follows:

➤ Non-insulating glasses:

➤ Integral wired glass

➤ Laminated wired glass

➤ Monolithic ‘borosilicate’ glass

➤ Monolithic ‘soda-lime’ glass

➤ Laminated clear ‘soda-lime’ glass

➤ Ceramic glass

➤ Laminated safety ceramic glass

➤ Insulating glasses:

➤ Intumescent multi-laminated soda-lime glass

➤ Intumescent ‘gel-filled’ glass

➤ Partially insulating glasses:

➤ Intumescent laminated glass

➤ Radiation control glasses:

➤ Coated soda-lime monolithic glass. Any change in the glass type without a modification in the glazing system has the potential to reduce the performance to as little as 10% of the needed level, or 3 minutes instead of 30 minutes, in many circumstances. It is essential that the technique of installation, as well as the material and design of the structure to be glazed, adhere precisely to the glass manufacturer’s guidelines.

Steel sandwich panels

The usage of lightweight sandwich panels in buildings is on the rise; they are frequently made with flammable plastic core material for thermal insulation. Sandwich panels combine the strength of the exterior material with the insulating qualities of the interior core. As a result, they have gained popularity as a building material that permits simple and speedy assembly. Sadly, this sort of panel has been linked to the quick spread of fire and early collapse of a number of huge structures. Any cavities or concealed spaces that may be generated by sandwich panels must be effectively safeguarded against concealed, internal fire spread.

Openings in compartmentation

Compartmentation is essential for the building’s and its residents’ safety. Yet, a structure with compartmentalized floors and walls has extremely little utility. There are always instances in which a compartmentation wall or floor must be “breached” in order for inhabitants to move about and services to be installed. When these required compartmentation breaches are created, it is crucial that the compartment maintains its integrity against fire spread.

The Building Regulations Approved Document restricts the types of apertures permissible in the floor or walls of a compartment to:

➤ Doors and shutters with the appropriate fire resistance

➤ The passage of pipes, ventilation ducts and other services

➤ Refuse chutes of non-combustible construction

➤ Atria designed in accordance with specific rules

➤ fully enclosed protected shafts

➤ Fully enclosed protected stairways.

Doors with the proper fire resistance and the passage of pipes, ventilation ducts, and other services are the two types of openings in compartment walls and floors that are the most difficult to maintain after a structure is occupied. Several times, inadequate fire risk management has led to breaches in compartmentation that have caused relatively small fires to spread and grow to tragic proportions. Fire doors that are malfunctioning or wedged open are a common cause of compartmentation breaches, as are contractor activities including the routing of new services via compartment walls or floors without the requisite reinstatement of the compartment’s integrity.

Fire doors and shutters

Fire doors-fire doors are installed not only to allow passage through a fire compartment wall, but also to shield evacuating individuals from the heat and, more crucially, smoke generated by a developing fire. In addition to the fire resistance of the door and its assembly, it is essential that the door restricts the flow of smoke to protect escape routes and avoid smoke damage to the building. This is accomplished by ensuring that the door effectively self-closes and is fitted with two types of seals: an intumescent strip that expands when it becomes hot and forms a fire-resistant seal around the door, and a cold smoke seal, which typically consists of bushes or felt material and prevents the movement of cold smoke. The fire resistance of doors is certified using the BS 476 testing process. Fire doors can only attain a certified rating when assembled with other components, such as door frame hinges, door handles, and glazing. So, it is clear that the fire resistance of any given door depends as much on the overall assembly as it does on the door itself.

Fire shutters – There are times when it is impractical to protect a compartment opening with standard doors. There are a number of systems that can be utilized to protect a wide opening in compartment walls and flooring, such as:

➤ Fire resisting roller shutters (FRRSs)

➤ Sliding doors in large scale industrial applications

➤ Fire curtains in, for example, the proscenium arch of a theatre.

These systems all operate according to the same fundamental principles. Nonetheless, FRRSs are the most frequent approach for securing wide openings. FRRSs are typically installed to guard openings such as:

➤ In kitchen walls

➤ In party walls between two premises

➤ Between floors in shops fitted with escalators in corridors

➤ Protecting atriums or escalator wells

➤ Protecting vehicle entry openings

➤ Entrances to retail stores from shopping malls

➤ Escalator hood shutters.

Passage of pipes, ventilation ducts, chimneys and other services

In the same manner that fire spreading through concealed cavities poses a significant risk, openings in compartment walls and floors that offer no fire resistance make buildings vulnerable to fire spreading. While designing, constructing, and managing buildings, it is essential that all pipes, ventilation ducts, and other services that pass through a compartment wall or floor are equipped with proper “fire stopping.”

In many instances, services and compartment holes are “stopped” with cement mortar or another noncombustible substance. Nonetheless, proprietary fire stopping and sealing technologies are now commercially available and are frequently employed to close the region surrounding a breach in the compartmentation. These unique technologies, such as intumescent pillows, provide a cost-effective and adaptable approach for controlling the spread of fire. Other typical fire-resistant materials include:

➤ Gypsum-based plaster

➤ Cement- or gypsum-based vermiculite

➤ Mineral or glass fibre

➤ Ceramic-based products

➤ Intumescent materials including pillows, mastics, etc.

In addition to the stopping around pipes, ducts, etc., where there is the potential for fire to spread within ducting, fire dampers should be fitted to maintain the integrity and form part of the fire resisting compartment

10.3 Fire alarms and fire-fighting

Fire detection and alarm systems

Employers and occupants of a building must make adequate and reasonable arrangements for detecting fire and sounding the alarm if they want to ensure the safe evacuation of their employees and guests. In certain instances, such as in small detached workplaces, it may be fair to rely only on the occupants to notice a fire and verbally alert others. It may be claimed that a reasonable level of safety for the occupants was thus established. For slightly bigger spaces, it may be deemed necessary to supplement this extremely basic system with a manually activated, electrically powered fire alarm.

For larger properties or where owners/occupants/responsible parties choose to give a higher degree of construction, an automatic method will be employed. According to statistics from the Home Office, 67 percent of all fires in commercial properties occur after 6 p.m. and on weekends. Implementing a system that automatically detects and raises the alarm will considerably boost both life and property safety and might bring with it the following advantages:

➤ Detection of fires in unoccupied areas of the structure, such as storage and boiler rooms, at an early stage.

➤ Early notice of a fire to the occupants, allowing for effective evacuation

➤ The operation of additional safety devices, such as:

➤ Automated door closers and stairway pressure relief systems

➤ Shut down air conditioning and ventilation plant

➤ Making fire control systems operational

➤ Starting ventilation systems or fans for smoke control

➤ Opening doors or ventilators

➤ Functioning door release mechanisms, etc.

➤ Notification of the fire department in a timely manner, allowing for an early start to firefighting operations and a reduction in fire spread.

Types of automatic fire detection and alarm systems

Protection of life and protection of property are the two primary purposes for which fire alarm systems may be installed in buildings. Undoubtedly, a system designed to protect life will have repercussions for property security, and vice versa.

Methods of detection

Manual – Manual call points will be made available for fire detection systems that allow for human detection.

The call points must:

➤ Be located so that egress cannot be made from a floor or building without passing one

➤ Be conspicuous

➤ Comply to BS EN 54-11 type A, i.e. be operated by a ‘single action’

➤ Be protected from accidental operation.

Automatic – Fire can be automatically detected in a variety of ways, and gear developed for the task must be sensitive to at least one of the phenomena associated with fire, namely the presence of heat, smoke, or flame. Several detection methods may be included into the same system in order to select the most appropriate detection method for every given location. In addition to their mode of operation, automatic detectors can be categorized as either point detectors or area detectors (i.e. equipment that detects a fire at a particular location or area detectors that are capable of detecting a fire over a wide area). Some point detectors are designed to perform the combined functions of fire detection and alarming. Historically, these sorts of detectors have been mostly used in the home, but they are now widely employed in workplace fire alarm systems.

Smoke detectors – The point smoke detector is the most prevalent method of detection. There are two varieties of detection units:

➤ Ionisation units. These devices detect all sorts of smoke containing microscopic particles, however they respond most quickly to smoke created by flames such as chip pan fires (very sensitive). The detector in these units comprises of a little amount of radioactive material that detects any unseen airborne smoke particles. When smoke particles are recognized, the alert is transmitted to the panel.

➤ Optical units. These devices detect all sorts of smoke, but they are perfect for detecting smoke with bigger particles, such as that produced by burning furniture. Regular pulses of ultraviolet light are sent to a detector in this unit; if the light is stopped from reaching the detector, an alarm signal is issued to the panel.

Heat detectors – These detectors function by detecting ambient heat. There are two separate modes of operation. Some are designed to operate at a specific temperature, while others detect the quick “rate of rise” of temperature that is characteristic of a developing fire. They are frequently used in kitchens, where smoke detectors would continuously activate due to the kitchen’s routine procedures.

Flame detectors– Detectors of flame function by identifying the exact light wavelengths emitted by a fire. They are utilized in situations that require immediate fire detection, such as petrochemical complexes.

Portable firefighting equipment

Typically, fire extinguishers are intended to combat multiple types of fire. Red is the color of all extinguishers that comply with current rules. In order to identify the exact type of extinguisher, a color-coded panel comprising at least 5 percent of the body is displayed. The size of the extinguisher offered for a certain area is determined by the fire hazard and the number of people who may need to use it. There are seven fundamental types of fire suppression equipment:

➤ Water

➤ Aqueous film forming foam (AFFF)

➤ Foam ➤ Dry powder

➤ Carbon dioxide

➤ Wet chemical

➤ Fire blanket.

Water – Water extinguishers are most typically seen in offices and other workplaces where carbonaceous materials, such as wood, paper, and plastic, are combustible. By cooling, water extinguishes the flames. Contemporary extinguishers are of the stored pressure kind, in which the pressure is supplied by a small CO2 cylinder within the extinguisher, similar to a soda siphon; alternatively, the body of the extinguisher can be pressurized. The water is applied to the fire via a discharge hose, which eliminates the need to move the extinguisher manually back and forth. The internal pressure of the extinguisher is shown on the cylinder’s neck.

AFFF – AFFF extinguishers are nearly identical to water extinguishers, with the exception that they contain a foam additive (aqueous film-forming foam) that boosts the efficacy of the extinguisher and, as a result, produces a faster knockdown with fewer media. By cooling, AFFF extinguishes the flames.

Foam – Foam extinguishers are constructed similarly to water extinguishers, with the foam being discharged from the cylinder by stored pressure. The foam is produced by aerating the premixed foam through a specific adapter at the discharge hose’s end. The foam floats on the burning surfaces of oils and other flammable liquids because it is less thick than water. It extinguishes the fire through suffocation, or by preventing air from reaching the fuel.

Dry powder – The dry powder is released from the extinguisher by the CO2 cylinder’s stored pressure. When the CO2 is activated, the dry powder becomes liquid and is discharged through the hose to the nozzle. Dry powder extinguishes fire through suffocation, or by creating a barrier between the burning fuel and the air. It is the only extinguishing agent that can effectively combat fuel-flowing fires.

Carbon dioxide (CO2) – They only contain CO2 that has been pressurized to the point where it is a liquid. When the control lever is depressed, liquid CO2 is expelled through the discharge tube. A horn is installed at the end of the tube to reduce the flow of pressurized CO2 and steer it toward the flames. These extinguishers function by smothering, i.e., they replace the air around a fire with an inert gas that does not promote burning. CO2 is the sole medium that may be used safely to extinguish fires involving electrical equipment; nonetheless, it has several disadvantages:

➤ As a result of their extremely loud operation, they can distract the operator.

➤ They work for only a little time; the smaller ones may only last 12 seconds.

➤ They do not extinguish the fire, therefore it can quickly rekindle unless CO2 is periodically administered.

➤ They do not do their duties in an open place where drafts could cause CO2 to scatter.

Element 10: Fire

10.1 Fire principles

10.2 Preventing fire and fire spread

> eliminate/reduce quantities of flammable and combustible materials used or stored

> control ignition sources, including suitable electrical equipment in flammable atmospheres

> use good systems of work

> good housekeeping

10.3 Fire alarms and fire-fighting

10.4 Fire evacuation

10.1 Fire principles

The fire triangle: sources of ignition; fuel and oxygen in a typical workplace; oxidising materials

The fire triangle

The “fire triangle” is a basic illustration of the three variables required for a fire to start and continue burning after it has begun.

All substances are capable of combustion if sufficient heat is applied to cause the molecules to decompose and emit vapour.

As the vapour or gas is produced, it is that which ignites, resulting in the release of further heat and the propagation of further reactions – the fire process has commenced.

As the material involved in the combustion or fire decomposes, the remaining material has less ability to respond, leading the fire to eventually die down and extinguish.

The decomposition of the material in this manner is known as pyrolysis, and the smoke produced by a fire is composed of unburned pyrolysis byproducts.

Fire initiators

There must be sufficient heat from an initiator or ignition source for a fire to ignite. There are ignition sources in every business and home. Open flames, hot surfaces, electrical sparks (internal or external), electrically generated arcs, friction (machines), chemical reactions, and even the compression of gases may be sources of ignition.

From the statistics, it is feasible to determine the sources of ignition and the number of times these “initiators” have been deemed to have caused a fire:

➤ Smokers’ materials

➤ Cigarette lighters

➤ Matches

➤ Cooking appliances

➤ Space heating appliances

➤ Central and water heating devices

➤ Blowlamps, welding and cutting equipment

➤ Electrical distribution

➤ Other electrical appliances

➤ Candles

➤ Other/unspecified.

In addition to those sources identified above other common sources of heat in the workplace include:

➤ Electrostatic discharges

➤ Ovens, kilns, furnaces, incinerators or open hearths

➤ Boilers, internal combustion engines or oil burning equipment

➤ Lightning

Fuel sources

Everything will burn given sufficient heat and the appropriate conditions. Obviously, some things will burn more readily than others, such as wood shavings or dust burning more readily than a solid piece of wood. These fuel sources are often classified into three categories (although these are sometimes subdivided).

Solids

Wood, cardboard, paper, hardboard, soft furnishings such as carpets and drapes, plastics, foam rubber, and even metal are examples of carbonaceous materials.

While the structure of solids is based on firmly formed particles, materials such as metals (unless reactive, i.e. magnesium) are extremely difficult to combust and require the use of considerable heat sources.

Certain solids are extremely “reactive” and may be categorised as “flammable” solids in accordance with UN Transport standards; they will be readily identified by a label or sign.

Liquids

Due to their capacity to emit vapour, they are significantly more likely to contribute to a fire. Liquids such as gasoline, paraffin, white spirit, thinners, varnish, and paints pose a substantial danger. Chemicals such as twin pack adhesives, acetone, and toluene also emit vapours, and these liquids provide an even larger risk due to their low flashpoint.

Gases

Common flammable gases in the workplace include natural gas and liquefied petroleum gas (LPG). The most popular LPG kinds stored in pressurised cylinders are butane and propane (i.e., for cooking, heating, plumbers’ torches, etc.); also, dissolved acetylene and oxygen mixtures are used in welding operations. As with the flammable vapours emitted by flammable liquids, gases not only pose a considerable risk of fire but also of explosion.

Dusts

Several common and occupational elements can generate dust, including wood, coal, grain, sugar, synthetic organic compounds, and certain metals. If ignited, a cloud of flammable dust in the air can erupt dramatically.

Oxygen

Oxygen is the final element of the fire triangle to be explored. Oxygen is a component of the air we breathe (19.6 %) and is therefore available in all areas where people may survive.

As previously said, the oxygen supply can influence fire behaviour; therefore, understanding how the supply can be increased or decreased is essential when considering control elements. Ventilation and air handling systems, as well as oxygen cylinders (for medical use and hot work/cutting work), can increase the oxygen supply. Oxygen can also be released by chemical reactions, namely those involving ammonium nitrate (fertilisers), sodium chlorate (pesticides), hydrogen peroxide (water treatment, hair care), and chromate (variety of industrial processes). It should also be noted that oxidizers exhibit very exothermic reactions when they come into contact with other chemicals, especially flammable ones. Oxidizing agents can also boost the combustibility of chemicals that do not ordinarily burn easily in air, or they can reduce ignition temperatures to the point where materials burn more quickly and fiercely..

Classification of fire

The classification of fires according to their types. Five classes are outlined in BSEN 2. The classifications help identify not just the type of fire, but also the type of extinguishing media required to extinguish or control the fire.

Class A – fires involving solid materials, typically of an organic nature, such as wood, cardboard, paper, hardboard, and soft furnishings such as carpets and draperies, where combustion typically occurs with the creation of blazing embers.

Class B – fires involving flammable liquids, such as gasoline, paraffin, white spirit, thinners, varnish, and paints, or flammable solids, such as candles (wax) and fats.

Class C – fires involving gases like LPG (butane, propane) or natural gas.

Class D – fires involving metals such as sodium, lithium, manganese, and aluminium in swarf or powder form

Class F – fires involving cooking substances such as vegetable or animal oils and fats in cooking gadgets. These fires are very difficult to extinguish because they retain a substantial amount of heat, allowing the chemical reaction to resume.

Notably, there is no classification for electrical fires, as electricity does not involve any combustible materials that can be put out. Electrical circuits and appliances, cables, etc, can be extinguished either with a non-conductive extinguishing substance or by isolating the supply and extinguishing the real material (given its own “class”).

Principles of fire spread

After a fire has started and there is sufficient fuel and oxygen to maintain it, there are three recognised routes for it to spread within a structure: convection, conduction, and radiation. There are also the impacts of direct combustion and heat transport to consider.

Convection

Owing to its qualities, hot air rises; this is seen when smoke from a bonfire rises and disperses into the atmosphere or when a fire is lit in a grate and rises through the chimney. When combustible materials are subjected to extreme heat, they emit a flammable vapour that initiates the convection process. When heated, these vapours expand and become less dense than air. When they ascend, they leave a region of low pressure that is immediately replaced by cooler, unheated air. This fresh air is subsequently combined with the vapour and heated, contributing to the increase in temperature. It is a cyclical process that continues to assist the fire process. The most common source of fire spread within buildings and structures is convection. During a fire, hot gases and vapours (smoke and heated air) will rise to the highest accessible level through stairwells, lift shafts, and service risers. They then establish a layer at that height, which they use to spread out horizontally until they are discovered. When the temperature of the smoke and, subsequently, the hazardous gas/vapour layer rises, heat is reflected downwards and may burn nearby combustible things. Recent research also indicates that the unburned fuel (pyrolysis products that have not been burned) in the smoke can reignite when it reaches its spontaneous combustion point, resulting in a significant increase in temperature. This temperature increase has the potential to create a flashover or explosion if a fresh supply of oxygen is introduced (window glazing fails). Clearly, there is a significant difference between a fire that starts in a confined location, such as a structure, and one that starts in the open air, and this must be taken into account when designing buildings to prevent smoke and fire spread and allow people to escape safely.

Convection and the effects of smoke

Although it is essential to limit the spread of fire within a structure, it is also crucial to consider the rate of spread and the impact of the smoke produced by the fire as it burns. As a fire spreads, it will generate vast volumes of smoke, which will typically move ahead of it and rapidly fill a structure. This creates a poisonous and/or suffocating hazard for the building’s inhabitants. Smoke also lowers visibility and obscures escape routes; this, combined with people’s natural aversion to move through or into smoke, can cause or exacerbate panic, which leads to confusion and reduces the likelihood of safe escape.

Conduction

Conduction is the transfer of heat through a substance. The ability of conductors to carry heat varies greatly depending on the type of material; for example, metal is a significantly better conductor than brick. It should be emphasised that conduction can occur in solids, liquids, and gases; nevertheless, in the context of building fires, solids are the most common conductors.

A fire in one room can spread to adjacent rooms via heat conduction through the building’s structure (walls, ceilings, etc.), particularly through metal pipes or frames used in building construction. The heat can then ignite substances in direct contact with the surface or radiate away from it. This can boost the temperature of nearby materials to the point of spontaneous combustion, thereby spreading the fire. The relative conductivity of building materials is consequently a significant aspect of a structure’s or building’s fire resistance.

Radiation

Radiation is the transport of thermal energy in the form of electromagnetic waves that heat solids and liquids (but not gases) in its path. Paths of fire radiation require no interaction between bodies and flow independently of any object intervening in space. If electromagnetic radiation is not absorbed by fire-resistant materials, it can radiate through windows and cause fires to spread to many compartments/rooms. As with a heater or an open fire, fires can spread to combustible goods left to dry or from one structure to another when heat from a fire radiates through windows to an adjacent building, igniting combustible contents in the second building..

Direct burning

When combustible materials come into direct contact, there is a physical transfer of heat from the ignition source to the combustible material, resulting in the release of volatile substances that ignite and spread the fire. It is true that direct burning utilises one or more of the previously discussed methods of heat transfer; however, it is appropriate to mention this method because a significant proportion of fires are ignited in this manner, and when heated to an ignition temperature by coming into contact with a burning material, it causes fire to spread.

Causes of fire

Accidental fires

The term accidental fire refers to all fires other than those set intentionally or maliciously.

There is a vast variety of causes for workplace fires. They will, to some extent, represent the function of the workplace. In many organisations, a workplace may be a vehicle, such as in the case of a long-distance truck driver employed by a transportation company. It is also beneficial to investigate the causes of fires in vehicles.

Considering the available statistics, it is clear that the most prevalent causes of significant accidental fires in the workplace fall under the following categories:

➤ Electrical appliances and installations

➤ Cookers, associated cooking equipment and installations

➤ Naked lights and flames

➤ Heaters and heating systems

➤ Chemical and LPG (hazardous materials)

➤ Smokers and smokers’ materials

➤ Waste and waste management systems

➤ Other significant causes.

Arson

Arson can be defined as the deliberate or willful act of lighting fire to a structure or piece of property, whether it be an industrial facility, a residence, a vehicle, or any other similar object. In the United Kingdom, arson has become the leading cause of big fires.

At its worst, arson can result in loss of life and major financial ramifications, as is the case with any fire. But, continuous and pervasive minor arson attacks also generate a very negative (and aesthetically damaging) tone in disadvantaged places and communities. In some locations, arson now accounts for 70% of all fires, and in some inner-city neighbourhoods, an astounding 82%. Over the past decade, the number of arson fires attended by the fire service in the United Kingdom has more than doubled, and now exceeds 85,000 annually.

During the same time period, the rate of increase in the number of casualties caused directly by arson assaults has been comparable.

10.2 Preventing fire and fire spread

As demonstrated in the preceding section on arson prevention and control, the preventative techniques for decreasing the risk of fire and explosion in the workplace are applicable to the vast majority of industry sectors. The primary causes of fire typically vary only in minute specifics and frequently involve hazardous operations and sites, e.g. COMAH sites; otherwise, the reasons are consistent, especially when the “human component” is involved. Thus, this part will cover broad recommendations, with specific topics explored under each of the sections. By formalising and disseminating a written policy, a complete prevention approach should incorporate the overall preventative and protective measures for each element addressed. The policy document should address the following:

➤ A description of the specific policy being handled, such as hot works.

➤ A section describing organizationally who is responsible for what, e.g., who is responsible for securing a contractor to test electrical equipment, or the role of personnel in doing visual inspections.

➤ Detailed procedures for conducting risk assessments and implementing controls, such as determining the number of fire marshals needed and their training, are required.

➤ Details of any monitoring or measuring of performance, such as the signing off of a permit to work system, should also be included, as well as whether they were completed adequately and run efficiently.

➤ How the aspects of the individual policies will be reviewed and audited to determine their efficacy or wastefulness. For instance, gas heating equipment that is no longer in use may still be included on an inspection aide memoire, the policy appears to still cover gas equipment, and individuals continue to get training in the safe use of gas cylinders..

Electrical appliances and installations

Electrical fires are second only to arson as the leading cause and hazard of workplace fires. A variety of management steps are likely to be incorporated into the management system described above in order to limit the risks connected with electrical appliances and systems. Only procure electrical appliances and equipment from a reputable (preferably authorised) vendor. Prior to acquisition, a risk assessment should have been conducted to ensure the equipment is safe and suitable for its intended use.

Portable appliance testing (PAT)

The frequency of inspections and tests should be determined by the kind of use for portable electrical equipment. Preferably, electrically portable equipment should include labels indicating that it has been inspected and tested and is in satisfactory condition.

More regular testing is conducted on electrical equipment used in harsher settings, such as construction and hilly operations. Electrical installations, whether temporary or permanent, as well as electrical equipment and apparatus, should be protected by a variety of measures, such as residual current devices (RCDs) that protect humans from electrical shock, fuses, and miniature moulded circuit breakers (MCCBs) that protect electrical equipment from overheating and short circuits. Provisions should be made to ensure that all electrical work on installations and/or electrical equipment is performed solely by trained, qualified, and competent electricians who are conversant with the relevant systems. Electrical safety systems such as those described above will also assist in reducing the risk of fire caused by vermin-caused damage to installation cabling; however, these systems should be supported by active management to control vermin in order to avoid or minimise the risk of fire from these areas. The hazards associated with electrical equipment, any special design difficulties, restrictions, and signs and symptoms of deterioration or wear should be explained to all staff members who will be using electrical equipment. To aid in controlling electrical safety, documented systems to provide documentation of testing, inspection, etc., as well as a defect reporting system, should be considered.

Cookers, associated cooking equipment and installations

The use of electrical cookers and cooking equipment necessitates the consideration of management systems that address electrical safety-related issues. In addition to the management methods described above, a planned preventive maintenance (PPM) programme should include heat-controlling devices such as thermocouples, as it is unlikely that portable appliance testing can completely eliminate the risks posed by such equipment.

Gas cooking equipment and installations must be installed by a Council of Registered Gas Installers member (CORGI). Installing gas to appliances should involve either fixed piping or protected/armored flexible tubing. LPG petrol cylinders must be located outside of buildings and shielded from unwanted intervention in the case of temporary cooking supply and installations (e.g., during construction). As technology progresses, petrol systems and appliances should ideally fail to secure themselves in the event of an emergency, like as a fire. It is expected that gas supplies to appliances and installations will be linked to alarm/detection systems that, when activated, will automatically shut off the gas supply. Notably, gas supplies should not be able to be re-energized after an emergency in a manner that allows gas supplies to “free flow” in the presence of an ignition source to regulate the gas release. With modern systems, such as those found in hotels and restaurants with big kitchens, an extra safety measure, such as the deployment of fixed firefighting installations, can be implemented. They will be discussed in greater detail in subsequent chapters. As with electrical testing, all systems should be subject to routine inspection and maintenance by a certified engineer in accordance with the manufacturer’s or installer’s maintenance programme.

Naked lights and flames

The most effective method for reducing fire risks from this source is to prohibit the use of naked flames in the workplace. Replacement of hot work and flame-generating equipment, such as oxy-fuel equipment, must be viewed as the initial step in lowering the risks associated with this area. In terms of practical operations, the use of compression plumbers’ fittings as opposed to soldered connections is a good example of a situation in which this substitution eliminates the danger totally. When the use of naked flames cannot be avoided, formal operating procedures, safe work systems, additional levels of supervision, and suitable levels of formal monitoring on a regular basis may be used to limit the risk. The burning of trash in the workplace or on a building site should be avoided at all costs, both because of the inherent fire risk and to maintain compliance with the Environmental Protection Act, which mandates the management of air emissions. When purchasing high-heat-emitting lighting devices, such as halogen lights, a risk assessment should be conducted to determine their suitability. If such units are necessary, control mechanisms, such as restricting their use to regions devoid of combustible materials and flammable vapours, should be considered. Ensuring that higher-risk lighting undergoes planned preventative maintenance, specifically on their retaining hinges and brackets, will guarantee that the fixtures remain upright and away from surfaces that could catch fire.

Heaters and heating systems